Research Centre for Surface and Materials Science

The RCSMS specialises in materials characterisation for academic and industry-level research.

The Research Centre for Surface and Materials Science (RCSMS) specialises in materials characterisation, in terms of composition and structure, from the very near surface to the bulk of the material. The facility is available to both University researchers and industry.

University of Auckland researchers from a variety of departments use the RCSMS, including the Faculties of Science, Engineering, and Medical and Health Sciences. However, researchers from other Universities and CRIs are welcome, and all training and support for researchers wishing to access these techniques for their own projects are provided by qualified RCSMS staff. The centre also consults with industry to assist with materials characterisation and research needs.

History

The RCSMS was established in 1988 as a centre for academic research and to serve clients from industry. It is unique in New Zealand both in terms of its equipment and the expertise it offers.

The original investment of approximately $800,000 to purchase the country’s first XPS instrument was drawn from “university, public sector and industrial sources”, including Comalco, NZ Steel, the Defence Scientific Establishment and DSIR.

In 1995, RCSMS took over management of the SEM previously managed by the Department of Chemical and Materials Engineering, and purchased an AFM. The founding principles were to provide a catalyst to cross-departmental collaboration whilst providing a service to industry.

Facilities and resources

The composition or microstructure of a material influences its performance in every way. Industrial applications of materials characterisation can be anything from failing adhesion in helicopter blades to suspect particles in a food product. Over the years, staff at the RCSMS have analysed everything from old Mazdas to Old Masters.

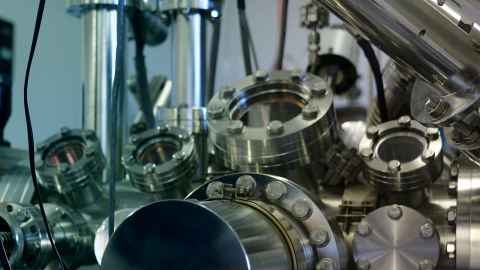

The current instrument base of RCSMS comprises instruments aimed at the characterisation of materials both at the “bulk” and at the “surface” level. Each technique is outlined in more detail in our facilities and resources information.

The instrument base is summarised here:

Scanning Electron Microscopy (SEM)

Fitted with a Field Emission Gun this is a high resolution instrument for imaging and topographical analysis. Useful for a very wide variety of applications where sample morphology needs to be investigated at high magnification.

Environmental Scanning Electron Microscopy (ESEM)

Imaging and topographical analysis in non-vacuum conditions.

Energy Dispersive Spectroscopy (EDS)

Using far smaller samples than traditional chemical techniques, material composition can be identified. Elemental characterisation (accessory on each SEM).

Electron Backscatter Diffraction (EBSD)

Crystal orientation and phase distribution analysis (accessory on ESEM) Based on the diffraction patterns obtained when an electron beam strikes a sample, it can be used to determine the crystal structure.

X-Ray Photoelectron Spectroscopy (XPS)

Surface chemistry characterisation. Most widely used contemporary surface characterisation technique, also known as Electron Spectroscopy for Chemical Analysis (ESCA).

Ultraviolet Photoelectron Spectroscopy (UPS)

Surface chemistry characterisation, particularly suited to valence band analysis (accessory on XPS). Used to study valence energy levels and chemical bonding; especially the bonding character of molecular orbitals.

Atomic Force Microscope (AFM)

A scanning probe microscope ideally suited to biological specimens and examining chemical interactions at surfaces due to its ability to image under fluids. Imaging and materials property analysis on the nano-scale.

High resolution metal coater

Sample preparation for SEM/EDS.

Transmission Electron Microscope (TEM)

Shared with SBS, scheduled for use from 2012. The TEM is essential for the study of atomic and nano-scale structure of materials.

University courses

The Centre offers professional courses for practising engineers and industry-relevant trade. It also contributes to undergraduate and postgraduate study and research.

University Courses

CHEMMAT 121 - Materials Science

CHEMMAT 724 - Advanced Materials Characterisation

In addition, technique-specific training for groups of graduate students and new staff can be run on request. Contact us below under "My people" to discuss your requirements.

Industry services

We provide training tailored to specific industry sectors. Issues with composition or microstructure can manifest themselves in a number of ways, anything from failing adhesion to suspect particles. RCSMS can help identify problems using state-of-the-art imaging and analysis, potentially saving your company time and money.

The RCSMS offers a wide range of skills and expertise with many years of experience, highly qualified staff and the latest tools. These techniques require a tiny amount of material for analysis and are non-destructive. Finally, each project receives a written report explaining the results of the investigation.

Recent examples include:

- A boat owner accused his neighbour of paint overspray onto his boat. Using a combination of EDS and XPS to compare paint samples the allegations were proved to be untrue.

- A wire manufacturer wanted to know the most effective cleaning method. By using XPS we were able to identify the residues left by different cleaning solutions. This enabled the client to make an informed choice as to what was the most suitable for them.

Our people

- Dr Steve Matthews

- Catherine Hobbis

- Dr Colin Doyle